Mushroom Leather Is More Than A Sustainable Alternative To Animal Skin

Can mushroom leather change the way we perceive, wear and consume fashion? As one of the world’s most purchased products, animal leather is the key to an $80 billion industry. However, the creation of animal leather requires the raising of animals, associated CO2 emissions, and toxic chemicals. The final material we call animal leather is heavily criticised by animal rights activists, environmentalists, and even fashion designers. Luckily, mushroom leather has the answer to all these problems and below you’ll see why.

What is Mushroom Leather?

Mushroom leather is a vegan-friendly material used as a sustainable and environmentally friendly alternative to animal leather. Mushroom leather is made from mycelium, the vegetative part of a fungus. A fungus (or fungi-plural) is any member of the group of eukaryotic organisms.

Eukaryotic organisms include microorganisms such as moulds and yeasts, as well as mushrooms. Fungi have their own kingdom, different than the other life forms on this planet, such as plants and animals. For that, mushrooms have unique capabilities.

The Uniqueness of Fungi

Mushrooms are already known for their tremendous benefits for the immune system, protection against cancer and even slowing down the ageing process. But fungi’s unique characteristics take their utility beyond food, to spiritual realms and beyond:

“Mushrooms bridge death and life, chaos and form, energy and substance. As our ancestors crossed continents, they ingested different mushrooms which led to an increase in the size of their brain, as well as their cognitive output,” said Paul Stamets, an American mycologist and author of the bestseller ‘Fantastic Fungi: How Mushrooms Can Heal, Shift Consciousness & Save the Planet’.

And more recently, there are certain types of fungi taking the world of fashion by storm.

“Reishi, our first product, is a new category of material that is neither animal nor plastic. This type of mushroom leather is the perfect example of art, science, and advanced manufacturing blending to improve supply chains for fashion and luxury,” said Philip Ross, founder of MycoWorks, a San Francisco start-up.

Right now, in the fashion industry, mushrooms are seen as one of the most sustainable materials to work with. Now, let’s see what mushroom fabric is, how it is made, and why the next generation of shoes and bags are going to be made of fungi!

What is Mycelium?

Mycelium is the network of filaments that form the underground thread-like structure of fungi. It is the branching structure of mushrooms, made from billions of tiny cells.

“The mushroom is a tiny little part belonging to this huge organism that lives underground, called ‘mycelium’,” Ross explains.

Mycelium grows in the ground, as tiny white threads, forming vast networks under the forest floor.

How Large Can a Mycelium Network Grow?

Well, let’s run a small comparison. When you think of the biggest organisms on Earth, the blue whale might come first to mind. Up to 30 meters long, blue whale weigh upward of 180 tonnes, making them larger than dinosaurs. However, the world record holder for the largest living organism on Earth is not the blue whale, but a fungus!

More specifically, the largest known organism in the world is a honey fungus living in the Blue Mountains of Oregon. The mycelium of this humongous organism occupies almost 2,400 acres (965 hectares) of soil, covering an area as big as 1,665 football fields. The honey fungus gets its size from its ability to fuse into a single organism.

“Mycelia from different individual honey fungus bodies meet and fuse to each other. For that, the connecting fungi must be genetically identical. When the mycelia fuse to each other, it creates large fungal bodies. This, in turn, blends extensive networks of fungal ‘clones’ into a single individual,” said soil scientist Jesse Morrison, from Mississippi State University.

Apart from growing naturally, mycelium can be cultivated in almost any kind of agricultural waste, from sawdust to pistachio shells. In nature, mycelium already does many things that benefit the environment. However, not many people know if mushrooms remain beneficial to the environment, once turned into a leather-like material… The answer is yes!

How is Mushroom Leather Made?

The idea of making leather-like material from mushrooms goes back to 2012. At that time, product designers Philip Ross and Jonas Edvard started experimenting with homeware products made from mycelium. Shortly after, they discover the versatility of this organic material.

“Mycelium can be used to make batteries, spaceships, and fashion. What I am trying to say is that the use of mycelium is scarily endless,” said Ross at that time.

The process of making mushroom leather begins with selecting and moisturising the right substrate. Substrates are materials that mushroom use as food and to grow on. Most common substrates are wood chips, straw, corn, and any materials that the mushroom can attach to and grow. Then, the substrate is dampened, put it into a bag and pasteurised. This process kills interfering bacteria, so the mycelium growing process is easier and quicker.

How Long Does It Take to Grow Mushroom Leather?

Once the mycelium spawns, it is inserted into bags. In the bags, the fungi start colonising the compound. From this point on, the making of mycelium leather requires only time and little attention. The growing process takes between two to three weeks and depends on several factors:

• Type of mushroom

• Type of substrate used

• Amount of sunlight

• Level of humidity

• Ventilation

When the mass of mycelium reaches the desired size, it is thoroughly extracted from the bag and compressed to get the expected shape and size.

Can You Make Different Types of Mushroom Fabric?

Right now, there are several ways to make mushroom leather. For example, during the compression procedure, the manufacturer can alter the material texture and colour. By adding dyes or changing the pressing form, the output can look and feel like any kind of animal leather, from cow to alligator, and python skin. Finally, mushroom leather is dried and ready for use. Moreover, these techniques are enhanced and improved every day.

How Sustainable is Mushroom Leather?

The making process of mushroom leather fits in the spirit of the circular economy and it is fully sustainable. This natural fibre is biodegradable at the end of its life cycle. Moreover, in this process, organic waste streams, such as agricultural waste, are valorised.

Also, this type of leather alternative can reduce the need for industrial animal agriculture, the leading supplier of animal leather for fashion.

One of the fascinating properties of mushroom leather comes from its positive environmental impact. A positive impact that goes beyond replacing animal leather and synthetic leather… Like solving the plastic pollution problem.

Mushroom Leather is Closed-Loop

Mushroom leather production is entirely closed-loop. Closed-loop manufacturing in fashion means that the used materials must come from post-consumer waste. Them these products are recycled, repurposed, and converted into eco-friendly products. In the making of mushroom leather, corn cobs, wood chips, and straw are post-consumer waste.

These discarded materials are mixed in with mushroom spawn to create mycelium, that later on is used to make vegan-friendly leather. Moreover, the waste resulting from the making of mushroom leather can be reused as a smoking product in beekeeping or as organic crop fertiliser. Overall, mushroom leather is an environmentally friendly material because it can be grown and produced without any polluting substances. And, at the end of its life, the material is completely biodegradable and compostable.

Mushroom Leather is Beneficial for Human Skin

In the apparel industry, mushroom leather is light-weight and very flexible, which makes it practical for a wide range of products. Moreover, tests conducted by Zvnder, a German company specialised in mushroom leather accessories show that: “When in direct contact with the skin, mushroom leather shoes have improved athlete’s foot condition. Even as watch straps, this material prevents skin irritation in people suffering from eczema.” Also, given its highly absorbent natural characteristic, mushroom leather can take in a lot of moisture.

As such, shoes made of mushroom leather do not require harmful chemicals sprays to get rid of bad odours anymore. Another decisive factor for human skin is the material’s unique capacity for holding a high amount of air. For that, the products made of this material are not only unusually light but also have an excellent insulating effect.

Most Common Mushrooms to Make Leather From

Right now, the most common type of mycelium used in mushroom leather comes from commercial Oyster mushrooms. But, there are companies out there using particular types of mushrooms seeking to obtain unique leather attributes. One of these innovative materials made from mushrooms is MuSkin. MuSkin is made from Phellinus ellipsoideus, a big parasitic fungus that grows in the wild and attacks the trees in the subtropical forests.

Another big mushroom leather manufacturer is Bolt Threads. The company is trialling several types of fungi, and Mylo is their most popular leather alternative to date. The company is very outspoken about the benefits of replacing animal leather with its unique material.

“As disposable incomes rise around the globe, we won’t be able to meet the demand for meat and leather consumer goods by exploiting the animals on this planet. By comparison, the mycelia we grow for Mylo is produced in days, without the resource intensity of raising livestock,” said the company’s spokesman.

Indeed, the making of mushroom leather requires minimal resource, water, and electricity. There’s no need to raise livestock, associated greenhouse gases, material waste and so on. In comparison to synthetic leather made from fuel fossil-based fabrics such as polyurethane and PVC, mushroom leathers are natural fabrics made from mycelium.

Mushroom Leather Vs Animal Leather

As a consumer, you must decide which material you prefer to wear. To do so, you have to compare and understand the differences in processing, manufacturing, and benefits of one, over the other.

At first glance, both types of leather look similar. However, these are two products remarkably different and we’ve put together 9 factors to consider before you make your choice:

1. Creation of pollution

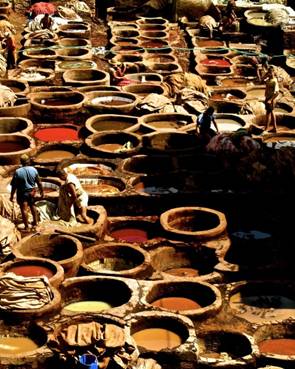

The production of animal leather creates enormous amounts of pollution. A piece of leather ready to be sold goes through a long process of tanning which requires numerous dyes and chemicals. These unnecessary artificial chemicals are toxic to people and the environment.

For example, one of the most common problem in tanneries is Chromium contamination. Chromium is a popular hardening agent used to create animal leather.

Tanneries produce water and solid waste which contain Chromium. Eventually, this metal makes its way into the water, air, soil, and the food of nearby communities. This chemical is known to cause liver failure, kidney damage, lung cancer, and premature dementia. It also makes the water undrinkable and it pollutes the marine life that is eventually used as food.

Finally tanning animal leather harms the environment by filling the air with eye-burning fumes. Research shows that the air and the soil around the tanneries are so toxic, the places where grass, trees, flowers, and crops once grew is now replaced by acidic foam.

Although regulations have been put in place to stop pollution since 1986, tanneries continue to use toxic chemicals. Sadly, animal leather pollution does not stop there.

2. The killing animals

Since most leather is a by-product of the meat industry, we must take into account this aspect as well. Raising animals to brutally slaughter and use their skin for fashion presents serious ecological and ethical issues.

3. Consumption of resources

According to the United Nations Food and Agriculture Organisation, the meat industry alone uses roughly about 30 per cent of the world’s ice-free land to support the production of cattle. It also uses one-third of the world’s fresh water, and accounts for nearly one-fifth of the world’s greenhouse gas emissions.

In comparison, mushroom leather does not require harmful chemicals, water, or energy expenditure.

4. Ability to recycle and reuse

Moreover, mushroom leather and its substrate can be reused again and again, as post-consumer waste. However, besides resources depletion, recycling and pollution, there are other factors to consider when choosing between these two products.

5. Time to manufacture

For once, the time difference that it takes to make these products is enormous! It takes three years to raise a cattle to a decent size that would allow the grower to get one piece of usable leather. Three Years!

On the other hand, as mushrooms grow at an exponential rate, it takes only a couple of weeks for the fungi to consume its substrate completely and to turn it into a leather-like alternative. Instead of waiting for the material, you, have to keep up with it!

6. Manufacturing flexibility

Another significant factor in the advantage of mushroom leather is its superb manufacturing flexibility. You can turn its surface look into any shape, size, or animal skin you can think of.

You can create different patterns, colours, and textures that regular leather would never be able to let you do.

“Fungi are very sensitive and will change their growth in relationship to how they’re being poked, moved, and so on. For example, if you put it in a cup, it would take the shape of the cup,” says Ross.

7. Level of quality

Another subject often debated is the quality and resistance of mushroom leather. The fragile look of mycelium might make you think that this leather can break apart like a piece of paper. However, there’s nothing to worry about the material ripping apart because several tests have shown the material to be as strong as deerskin!

8. Cost to make

Finally, the last comparable factor is its price. Right now, mushroom leather costs about the same as high-end animal leather. The price remains quite high because the amount produced remains low.

However, companies mentioned above are already working to produce higher volumes and predict a drop in the manufacturing cost of mushroom leather to just $5 a square foot. $5 per square foot is cheap than any type of leather anywhere in the world.

Moreover, a lower price than animal leather is key to making mushroom leather succeed in the future.

9. Mushroom leather smells like….

Oh, one more thing to consider, especially that we are in the fashion business here. How does mushroom leather smell?

Well, before we start talking about the smell of mushroom leather, you have to know that the ‘nice’ leather smell comes from the chemicals used to make it. Animal skin smells like meat.

However, as animal leather is a human-made product, it is packed with chemicals and other ingredients to give it extra shine, flexibility, smell, and so on. So, before I got my hands on a few patches of mushroom leather, I always wondered how it would smell.

Hard to describe the smell; it is not great but not bad either. To me, it has a natural smell, almost like the books at the library. One thing is for sure; it does not smell like animal leather.

Moreover, knowing what it takes to give animal leather its ‘fresh odour’ that some people love so much, I prefer the smell of mushroom leather.

What’s Next for Mushroom Leather?

If we take into consideration the above points, it is safe to say that mushroom leather has far more appeal to designers who choose to work with sustainable materials. And if you have not heard of luxury shoes made of mushroom leather, get ready as they’re coming soon. Many high-end designers are already using mushroom leather in their products, and you can order yours right now.

For example, Stella McCarney’s famous Falabella bag is made with Bolt Threads’ Mylo mushroom leather. Similarly, Nat-2 a German company known for their high-end sneakers uses sustainable materials and leather from the Tinder Fungus. This is a rare mushroom that gives the products a ‘vintage look’.

Conclusion

The possibilities of what we can create with mushroom leather are endless. However, as mushroom leather is arguably still a new material, it needs time to gain reputation, acceptance, and mass consumption.

Another two main problems impacting the adoption of mushroom leather are: People’s preconceived idea that animal leather is the best out there. The high cost associated with the making of this sustainable material. Nevertheless, given the sustainable wave that’s sweeping the fashion industry right now, it’s not long before mushroom leather gains higher production volumes and lower manufacturing prices.

Soon, we should see trendy bags, biker jackets, high-heels and accessories from mushroom leather in shops from all over the world. Also, before we close the article, know that there are several animal leather alternatives similar to mushroom leathers, such as pineapple leather, apple leather and even cactus leather.

As fashion designers, it is our job to be informed of the latest sustainable materials and take advantage of them. Being conscious of the environmental impact of our designs, in combination with creativity and material innovativeness, can open doors to a more sustainable future.

This article has not been edited by Fibre2Fashion staff and is re-published with permission from wtvox.com